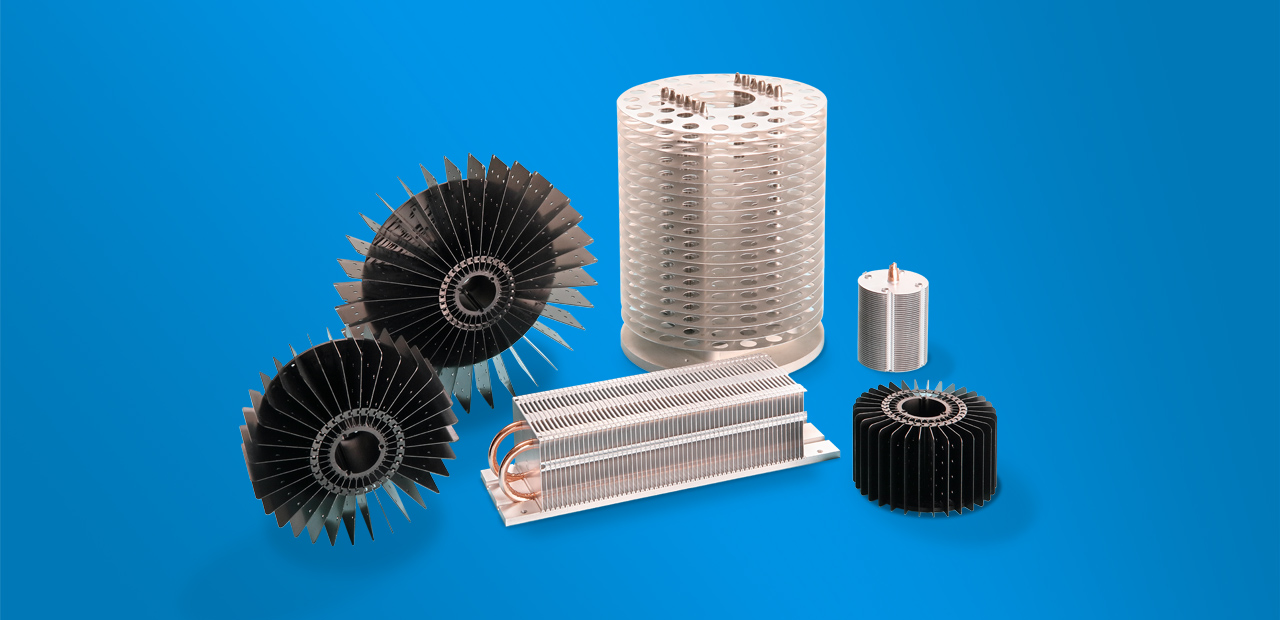

Skived Heat Sinks

Skived heat sinks are manufactured by taking a solid block of material and slicing thin fins from the block, without removing the fin from the block. Every other fin sliced this way is removed, to create spacing between the fins. The resulting heat sink structure has higher fin density compared to extruded heat sinks and also features an uninterrupted flow path for the heat because of its single-body construction, much like extruded heat sinks.

The excellent fin density of the skived heat sink structure makes it ideal for small spaces in liquid or forced air cooling. Skived heat sinks are thus used extensively in server cooling and networking/telecom circuit boards. Their low tooling cost also makes them cost-effective choices for high-ventilation applications in industrial equipment and automotive components.

Novark manufactures its skived heat sinks from aluminum and copper, in small to medium production volumes. The table below represents Novark’s standard manufacturing capability.

| Single Fin Thickness | Width | Length | Height | Fin Pitch | |

|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | |

| Max | 1 | 120 | 60 | 50 | – |

| Min | 0.1 | 25 | 10 | 5 | 0.2 |