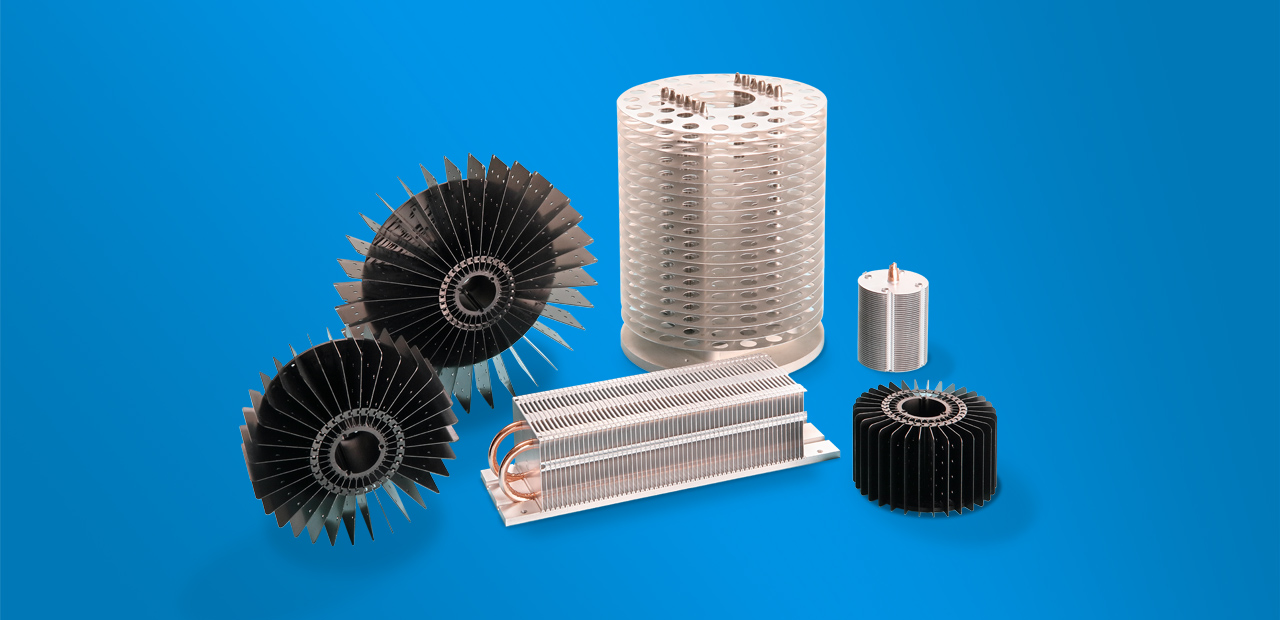

Interlocking Fin Heat Sinks

Interlocking fins are manufactured by machining and stamping the fins from thin metal sheets. The fins are then interlocked into a structure that is either soldered or press-fit onto the thermal module. The fins can be manufactured to incorporate channels for the insertion of heat pipes, improving the thermal performance of the fin structure. This fin type is also called “cartridge”, “zipper”, “snapped”, or “stack” fins.

These fins can be formed into highly customizable shapes with large fin surface areas and great fin density, and their construction is the most lightweight of the fin types. Because of the interlocking fin type’s lightweight construction and highly customizable fin shape, the applications are extremely varied, from consumer CPU cooling to aerospace and satellite cooling to data center cooling. This fin type is also very cost effective, providing excellent thermal performance on a budget.

Novark uses Aluminum and Copper to manufacture its interlock fin structure.

| Fin Thicknes | Fin Width | Fin Height | Fin Pitch | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Max | Min | Tolerance | Max | Min | Tolerance | Max | Min | Tolerance | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm |

| 0.2 – 0.5 | 150 – 250 | 20 | ±0.15 – ±0.30 | 60–90 | 6–7 | ±0.15 – ±0.20 | 2.5 – 4.0 | 0.8 – 1.5 | ±0.03 |

| Channel Protrusion Height | Interlock Feature Width | ||

|---|---|---|---|

| Max | Min | Max | Min |

| mm | mm | mm | mm |

| 1.4 – 2.0 | 0.7 – 1.3 | 5 | 4 – 5 |

This table is a representation of Novark’s manufacturing capacity. Please contact Novark for a custom Interlocking Fin Heat Sink design for your thermal management needs.