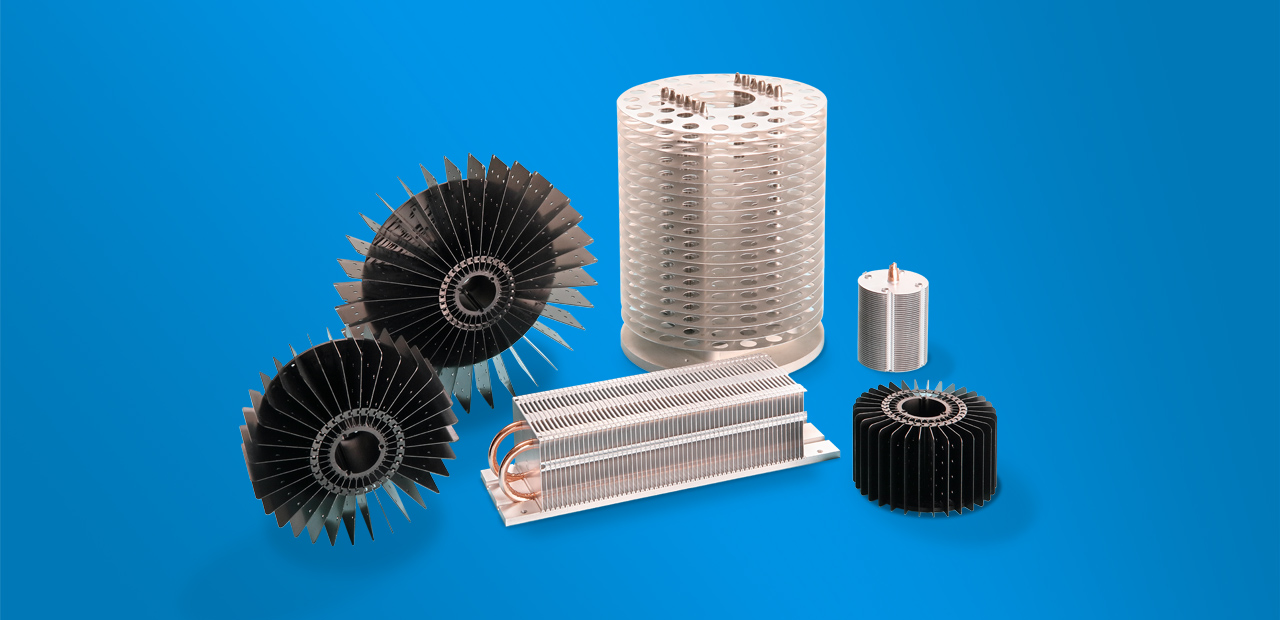

Folded Fin Heat Sinks

Folded fin heat sinks are created by folding a single sheet of metal multiple times to create a dense finned structure. This fin structure is then soldered, brazed, or bonded using thermal epoxy, to the heat sink base. This allows the base and fins to be of different materials, and allows a base with high thermal conductivity to be paired with lightweight fins.

This fin structure was originally developed for aerospace and satellite applications, because the fins can be manufactured with high fin density and very light weight. The flexibility of being able to attach a folded fin structure to most any surface allows for fast and efficient installation of the heat sink. Folded fins have higher thermal conductivity than interlock fins, due to being made from a continuous sheet. Folded fins are used extensively in liquid-cooling applications through installation in the liquid flow channel. Folded fins also have a very low tooling cost.

Novark manufactures its folded heat sinks from Aluminum and Copper. Novark also nickel-plates its folded fins to allow for soldering aluminum fins to copper heat sink bases. Novark manufactures plain style folded fins in-house, and works with its suppliers to provide lanced and ruffled fin types for its customers.

| Fin Thickness | Fin Width | Fin Height | Fin Pitch | Shape | |||

|---|---|---|---|---|---|---|---|

| Max | Min | Max | Min | Max | Min | ||

| mm | mm | mm | mm | mm | mm | mm | |

| 0.15 – 0.5 | 300 | 15 | 22 | 2.5 | 4.7 | 1.5–2.5 | Plain Ruffled Lanced |

This table is a representation of our manufacturing capability. Please contact Novark for a custom Folded Fin Heat Sink design for your thermal management needs.